- The ease of use of ProModel and in particular, the animation really help with conveying the concept. I am primarily focused on teaching process design & optimization and not necessarily training students to use software. Therefore, software that is difficult to use only ends up being a distraction. ProModel is great!

- How to download and install ProModel 7.5 I'm just showing the way to do it and all credits goes for for getting the program's files Down.

Customer Success | Training | New Product | Product Updates | Academic

It's September, But It's Still Summer

Customer Success - Automotive Materials / Inventory Management Analysis

Situation:

Phase 1: Model production capabilities to ensure plant was capable of increased production levels

Phase 2: Analysis of material handling, and replenishment strategies to Reduce Plant Inventory levels of sub-assemblies while maintaining production levels

Promodel: http://exe.io/vS9q.

- Focus was to look at Line-side and market place reorder points and quantities while taking into account variable lead times from their supplier to minimize the WIP held onsite

The material handling types and quantities were analyzed to right-size the labor and equipment for the specified frequency of deliveries

Analysis Showed:

Minimum level of inventory the client could keep Lineside and in their Marketplace represented a 50% reduction in inventory holding costs

Space needed for subassemblies lineside was significantly reduced making room for future growth

Current planned MHE level could not support the level of deliveries; client avoided potential issues by identifying in the model the specific number of resources needed to support the replenishment strategies.

TrainingReturn to top

Check out the training resources available to you on our training site.

New ProductReturn to top

We are proud to announce the LAUNCH of our latest addition to the ProModel portfolio of world-class solutions - PM SHIP. PM SHIP is a web-enabled, distributed simulation-based, capacity planning application. It provides a single, unified view of capacity and production today and into the future. Capabilities include:

- Automated capacity planning

- Foot printing

- Rule / constraint based scheduling

- Mobile access to capacity planning data

- Detailed history tracking and analytic visualizations / reports

Why PM SHIP?

Every day shipyards must make important resource capacity-related decisions. The need to meet or exceed deadlines and the inherent variability in supply chain and construction processes force shipyard management to be agile.

Unfortunately, current tools and methods do not adequately predict how today’s decisions will impact future operations and milestone dates. Any single variance in production schedules can have a “ripple effect” due to interlocking dependencies and constrained resources such as space, facilities, labor and transportation. If not managed properly, these “ripple effects” can lead to bottlenecks in a shipyard, significant delays and increased costs.

PM SHIP is a Continuous Capacity PlanningTechnology Solution developed to help shipyards optimize current operations by predicting and prescribing how to mitigate resource and schedule problems. It also provides a platform for management teams to help level workloads and plan future resource investments based on multiple possible demand scenarios.

PM SHIP is launching at the International Workboat Show Nov 28-30, 2018 in New Orleans. Come stop by ProModel’s booth 3932 to check it out or contact Michael Rice at mrice@promodel.com

Product Updates Return to top

Cost pressures, aging baby boomer population, and ever stricter government regulations on provider reimbursements continue to stress our nation’s healthcare system to its limit and beyond. We developed FutureFlow Rx ™ to help hospitals combat these conditions.

In a nutshell, we leverage existing hospital data, machine learning, and modeling & simulation to do 3 things:

- Predict the next 48 hours of your hospital

- Notify you of pending patient flow issues

- Prescribe how to make tomorrow better

- Reduce wait time for Beds, Providers, Transporters, EVS

- Identify discharge potentials

- Identify and free up needed high value beds

- Prioritize discharges based upon tomorrow’s capacity need

Learn more at FutureFlowRx.com.

FutureFlow Rx Dashboard

Process Simulator 2019 is coming before the end of the year with a new look and feel and some significant new capabilities. It will support Office and Visio 2016 64-bit and the following features:

Dockable Windows

All element property windows and tables have been redesigned and will be dockable within the Visio application workspace. This will allow you to keep them open and out of the way so your diagram view space will be clear for quicker modeling changes.

Referenced Hierarchical Models

Submodels will now have the ability to be referenced in addition to their current capability of unique instances. This means that activities linking to the same submodel at different points in your diagram will send their entities to the same instance of the submodel (and not just unique copies of that submodel).

Global Elements Across Pages

In support of the referenced submodels, all model elements (e.g. activities, resources, variables, attributes, macros, etc.) will be globally accessible across pages. This will also allow you to utilize multiple pages to build your model without the use of the submodel construct.

Read/Write Data to Text Files

Write out data to a text or CSV file for model troubleshooting/verification, or to log custom statistics to be imported and manipulated in Excel or another data analysis tool.

Find and Replace

Process Simulator 2019 will introduce its own find and replace capability, separate from Visio, and will search across its elements and objects only. It will even automatically bring the shape into view and open the associated property or field that the text is found in.

Model Compile Optimization

The compile time prior to simulation should be quicker, not only due to internal optimization, but also when animation is disabled or no changes were made to the model since it was last simulated.

Localization in Other Languages

Process Simulator will also be available in German, Portuguese and Spanish languages.

Academic Return to top

Dr. Linda Ann Riley's (Univ. New Haven) Innovative Teaching Approach for ProModel and Process Simulator

I have been teaching ProModel for the past 20 years and most recently in the capstone simulation course in the University of New Haven’s (UNH) M.S. in Engineering and Operations Management (MSEOM) program. In the course immediately preceding simulation, Six Sigma Quality Planning, I use both Microsoft Visio and Minitab as the software programs for course delivery. This brings me to the topic of this blog post: my experiences this past Spring introducing Process Simulator into the ProModel /Visio/ Minitab mix.Read the full first installment of Linda's blog post here.

Promodel software, free download

Product SummaryThe ProModel Optimization Suite is a discrete-event simulation technology that helps you to make better decisions faster. It is used to plan, design and improve new or existing manufacturing, logistics and other tactical and operational systems. It empowers you to accurately replicate complex real-world processes with their inherent variability and interdependencies, to conduct predictive performance analysis on potential changes, and then to optimize the system based on your key performance indicators. |

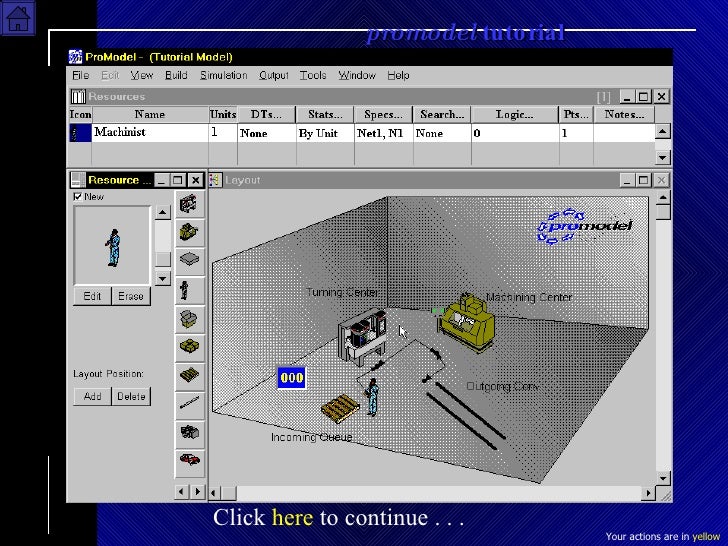

Learn About ProModelDiscover ProModel-specific training, tutorial, and how-to videos. Explore our training resources, online help, and view our pre-recorded webinars to help further your knowledge of ProModel. |

Watch an introductory video. |

Promodel Software Gratis Download

|